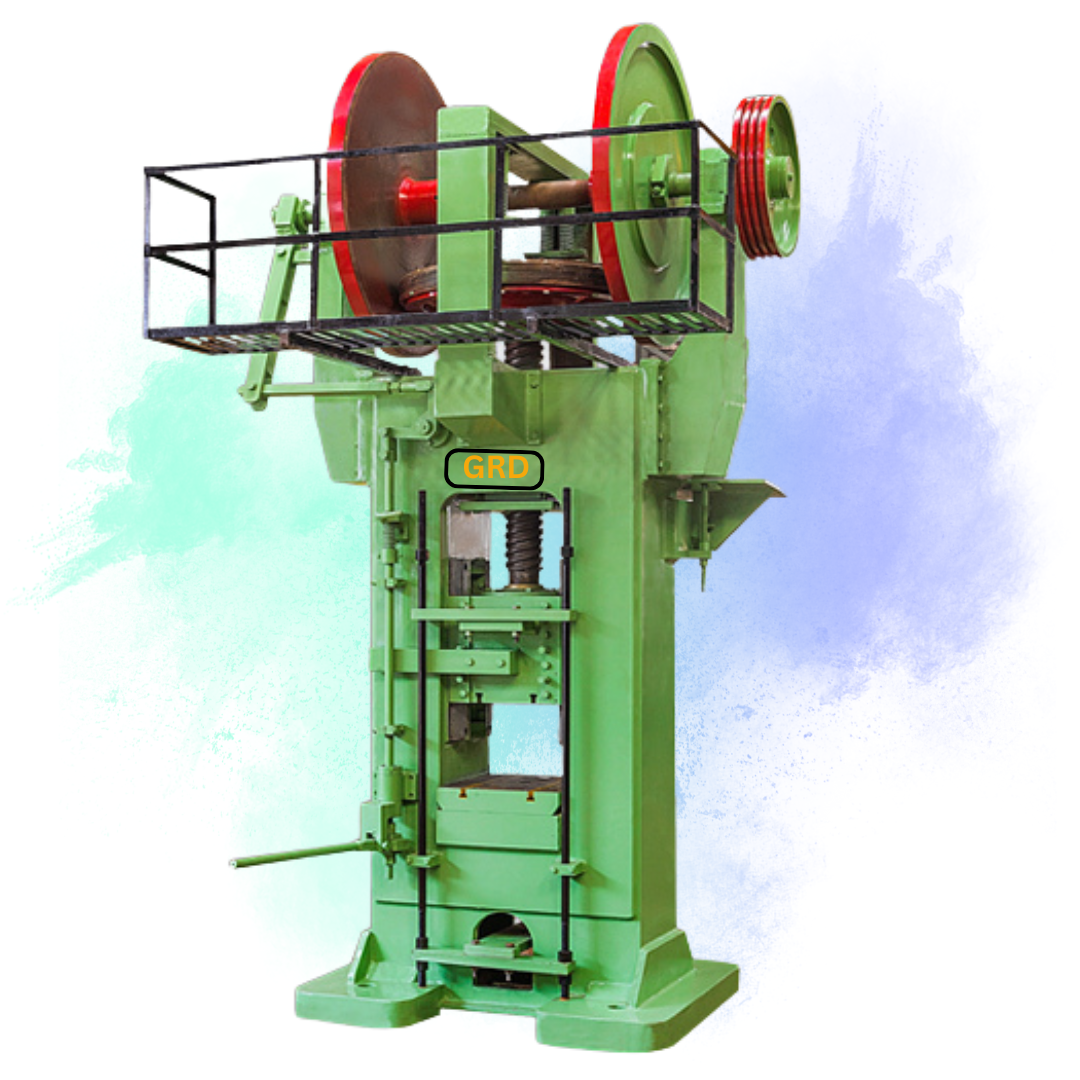

Down Stroke Friction Screw Press

Down Stroke Friction Screw Press – 50 Ton to 1000 Ton

GRD Mechanical Works presents the Upstroke Screw Forging Press, specially engineered for high-precision forging applications. Designed for superior efficiency and reduced mechanical stress, this press is ideal for:

Forging long bolt heads

Axle shafts

Nuts and other auto parts

These screw presses are highly dependable for both light and heavy-duty forging, ensuring consistent results and extended machine life.

Key Features:

Straight flywheel design — eliminates the need for a counterweight, reducing stress on both the ram and the screw

Adjustable strokes — precise control over every press cycle

Air-cylinder balanced ram — reduces ram weight impact and improves upstroke movement

Energy-efficient — consumes less power while maintaining high output

Top-positioned screw nut — ensures better control, accuracy, and performance

Upward axial movement — driven by a longitudinally fixed screw

Integrated ejector system — located at the lower ram section for smooth part removal

Advantages:

Reduced wear and tear on moving parts

Increased forging precision

Simplified setup and operation

Ideal for medium to high-volume production

Lower maintenance requirements

Suitable For:

Automotive component manufacturers

Bolt and nut forging units

High-precision forging industries